OSHA’s Focus Four: How to Prevent Fatal Construction Accidents

Construction safety is one of OSHA’s top concerns. So it makes sense that construction inspections comprise approximately 60% of OSHA’s total annual inspections. In 2019, according to the Bureau of Labor and Statistics (BLS), there were over 1,000 fatal on-the-job injuries to construction workers – more than in any other single industry sector. That equates to one out of every five work-related deaths in the U.S. that year.

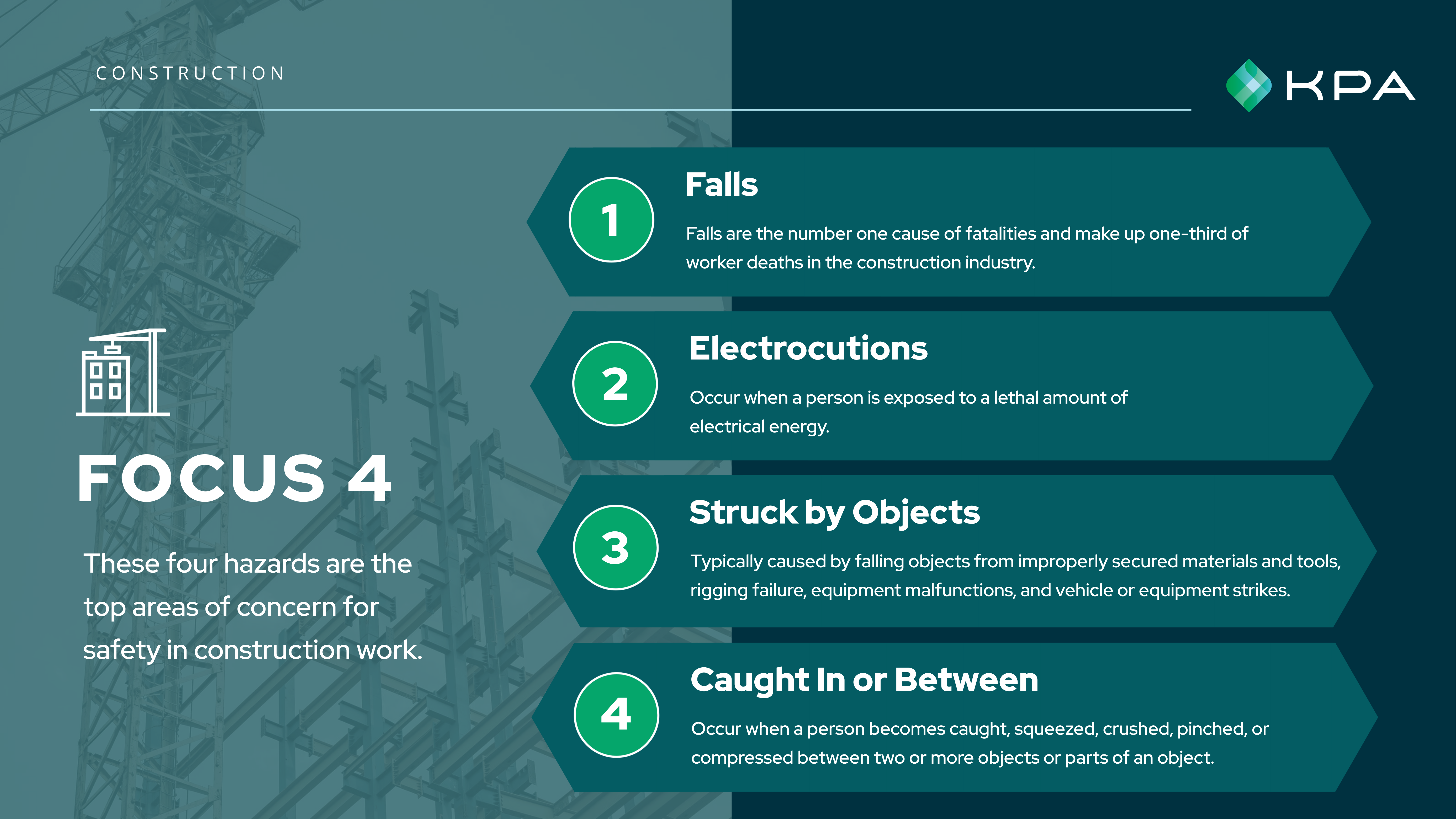

The Focus Four

The Focus Four or “fatal four” hazards are the industry’s leading causes of injury and death. OSHA created the Focus Four to highlight the primary causes of injury and death in the construction industry.

Falls

Falls are the number one cause of fatalities and make up one-third of worker deaths in the construction industry. Whether it’s a stumble and fall, or a fall from a roof, scaffold, ladder, or inappropriate footwear use, or even just walking through a slippery construction area.

Common causes of falls include:

- Unprotected sides, edges and holes

- Improperly constructed walking/working surfaces

- Improper use of access equipment like ladders or powered lifts

- Failure to properly use personal fall arrest systems

- Slips and trips

When working at heights, employers must ensure that the job is done safely. Employers should include safety equipment in their job budgets, and plan to have all the necessary equipment and tools available at the construction site. Analyze any potential fall hazards, such as holes or skylights and leading edges, then plan and select fall protection suitable for that work, such as guardrails, safety nets, or personal fall arrest systems (PFAS).

Electrocutions

Electrocution occurs when a person is exposed to a lethal amount of electrical energy. Electric shock occurs upon contact of a body part with any source of electricity that causes a flow of current through the skin.

Common causes of electrical accidents include:

- Contact with overhead powerlines

- Contact with live circuits in panels

- Poorly maintained cords and tools

- Lightning strikes

To avoid shocks and electrocution, workers must be aware of hazards such as

- contact with overhead or underground power lines,

- contact with energized sources,

- and improper use of tools and extension and flexible cords.

Workers should maintain a safe distance from overhead power lines, use ground-fault circuit interrupters (GFCI), inspect portable tools and extension cords, using power tools and equipment as designed, and follow lockout/tagout procedures.

Struck By Objects

Struck by accidents are caused by falling objects due to improperly secured materials and tools, rigging failure, loose or shifting materials, equipment malfunctions, and vehicle or equipment strikes.

OSHA recognizes four types of struck-by accidents, based on how the “striking” object moves including:

- Flying

- Falling

- Swinging

- Rolling

Workers can protect themselves from struck-by hazards by wearing the proper PPE, including high visibility apparel, staying clear of suspended loads, and always using the best safety practices.

Caught-in/Between

A caught-in or -between hazard occurs when a person becomes caught, squeezed, crushed, pinched, or compressed between two or more objects or parts of an object. Construction workers are killed when caught in or compressed by equipment or objects, as well as the hazards of being struck, caught, or crushed in a collapsing structure, equipment, or material.

Common causes of Caught In/Between Accidents include:

- Trench/excavation collapse

- Rotating or swinging equipment

- Moving machinery and unguarded parts

- Equipment rollovers

Preventing the Focus Four

There are several ways to prevent Focus Four accidents and fatalities.

Jobsite Inspections

Safety inspections are the most effective way to identify hazardous conditions at the jobsite. Construction sites, in particular, require constant monitoring and observations to stay on top of constantly changing safety issues. A good jobsite inspection program will identify risk exposures and include recommendations for addressing the hazards. Periodic inspections are important because they identify hazards and provide opportunities to fix them before injuries and accidents can occur.

Training

Every worker in the construction industry needs to understand and identify the many risks they face and what should be done to prevent them. Training on hazard identification should be conducted annually.

Personal Protective Equipment

There are many hazards at a construction site, and personal protective equipment (PPE) is a workers’ primary line of defense. Each item is designed to minimize exposure to certain risks of injury or illness. Each construction site and job duty should be evaluated for specific dangers, and the appropriate PPE required.

PPE may include but is not limited to hard hats, safety glasses, gloves, high visibility vests, boots, and fall protection.

Accident Reporting

Workers should understand that they must report unsafe conditions to a supervisor right away.

KPA EHS Helps Construction Companies Keep Up with Safety Standards

KPA has the tools and resources to ensure that your worksite is a safe environment for all involved. Manage your safety program in an all-in-one system designed to engage your employees, instill a culture of safety, and enable regulatory compliance. Contact us today, and we can show you how.