Three Ways to Use Data to Prevent Future Accidents

In the safety world, many organizations still rely on spreadsheets and binders full of outdated information. Here’s a practical look at what it takes to shift to a preventive EHS program using easily accessible data.

The benefits are huge: transitioning to an EHS culture focused on prevention and mitigation can keep your workers safer and save your organization money on insurance premiums, citations, and fines.

We live in an age of real-time, data-fueled dashboards that help business leaders make forward-looking decisions. And, luckily, there is software specifically designed for EHS that makes transitioning to a preventative program feasible. With all that data available to track, here are three ways to use safety data to get ahead of problems.

1. Track Leading (Not Lagging) Indicators

While lagging metrics are valuable for your insurance provider, they aren’t useful in preventing accidents or incidents where employees can get hurt. Metrics like DART (Days Away, Restricted, or Transferred) rate and incidence rates— they tell you what’s already happened in your organization.

To get preventative, you have to track leading indicators. These are things like

- identification and mitigation of workplace hazards

- completion of employee training

- consistent and proper use of personal protective equipment (PPE)

- modification of observed employee unsafe behaviors

This gets challenging in a traditional EHS setup relying on binders and spreadsheets because you have WAY more data points to keep track of.

2. Focus on Training

Safety doesn’t happen behind a desk; it happens on the facility floor, when dozens or thousands of individual workers consistently make the best and safest choice possible. But they need to know what those choices are.

For example:

- Are employees using the right PPE for their work? Are they wearing that equipment properly?

- Do employees know when they need to use PPE?

- Can employees recognize something that’s not up to code, whether it’s behavior or physical surroundings? If so, do they know what action to take when they do?

- If something goes wrong, will employees know what steps to take, or will they have to wait for a manager’s instruction?

- Are chemical safety data sheets easily accessible?

An entire workforce doing small things every day to uphold workplace safety standards has a much bigger impact on a facility’s overall safety than any single policy or guideline can have.

Think about how OSHA compliance officers approach their site visits. One of the first things they want to assess is whether the facility completes adequate employee training. If the answer is no, they’ll likely issue a citation.

But, if an OSHA inspector asks to see the safety datasheet for the chemical an employee is handling. The employee takes out a smartphone, opens an application, searches for the chemical, and retrieves the requested sheet on the spot. You’re looking at a smooth sailing inspection.

3. Make Your Data Easy to Access

It’s one thing to recommend tracking leading indicators and implementing more robust employee training. It’s quite another to put those things into practice.

Think about the last time you had to look something up in a binder…or a spreadsheet. Not the definition of easy. That’s why modern safety programs look to EHS software designed to be easily searchable, readily accessible, and designed to automate as much compliance work as possible.

When evaluating software, look for tools that:

- Offer training designed specifically for different employee roles.

- Make completing training accessible and easy (extra points if it can be done from a smartphone)

- Create a closed-loop system for hazard identification and mitigation.

- House a location-specific chemical inventory with easy-to-access SDSs.

- Generate OSHA 300 logs automatically.

- Help users determine when an incident has been recorded, whether it’s reportable, and in what timeframe.

- Provide analysis tools to help safety managers spot problematic trends and make recommendations to mitigate future incidents.

Purchasing the best software in the world does nothing if employees don’t use it. Make sure you pair rolling out any software with software-specific training and messaging from leadership about its benefits.

Data + Culture = A Safer Workplace

Believe it or not, the information you already have about your workplace and employees is the information you need to mitigate future accidents.

There’s a two-pronged secret to putting this information to work:

- Find a system that translates your data into actionable insights

- Cultivate an environment where everyone actively participates in improving health and safety.

By doing those two things, you can prevent incidents and accidents that would otherwise impact employees. This, in turn, can translate to not only happier and healthier workers but also cost savings and less down time—i.e., many of the key ingredients for sustained growth.

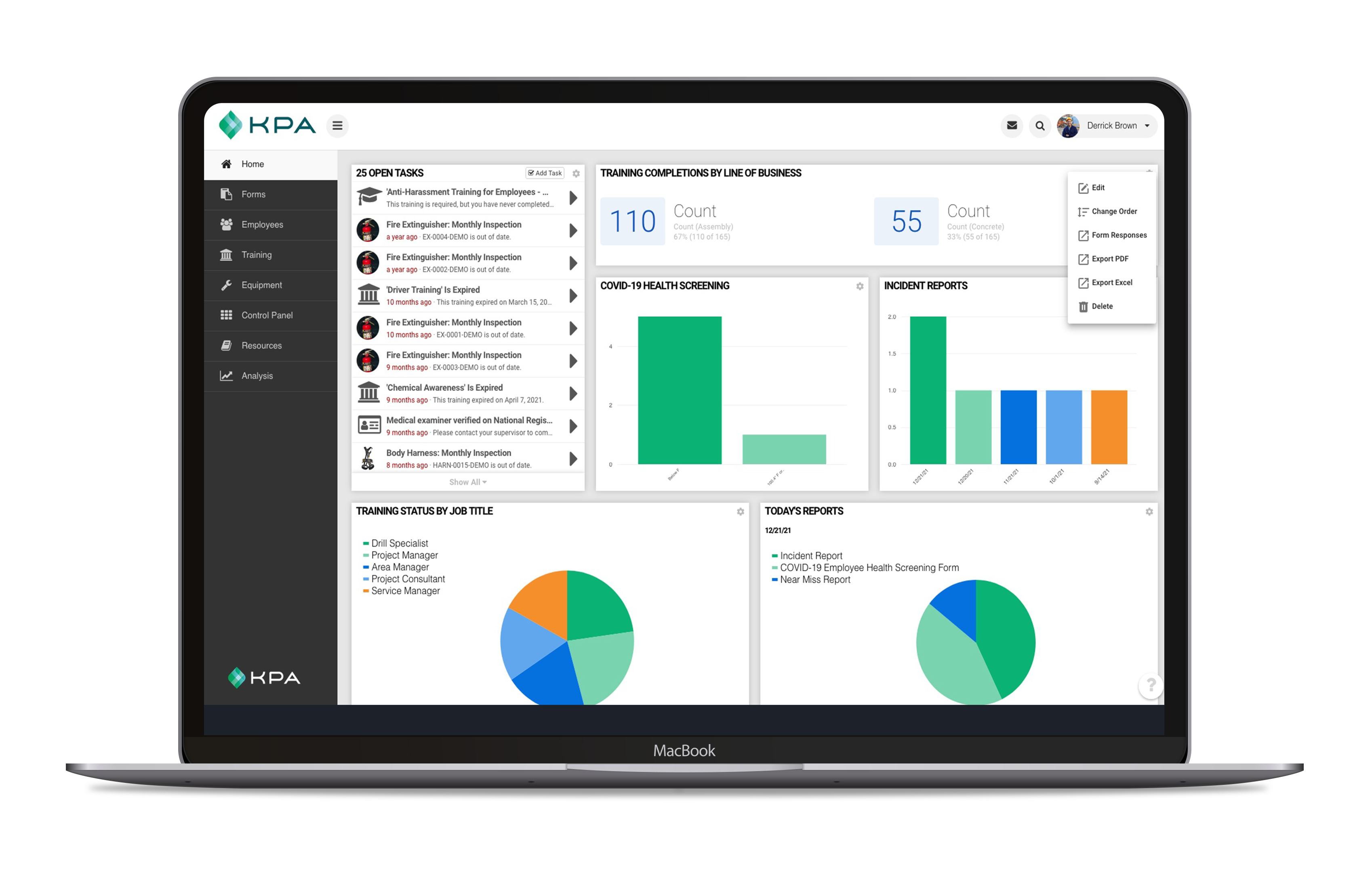

KPA Helps Businesses Take a Data-Driven Approach to Safety

KPA simplifies data visualization and reporting, giving users easy access to actionable insights into their EHS program performance. Your data is presented in real-time, so no delay or extra steps are required to access the information. The dashboards are configured based on features tailored to your business’s unique requirements, giving you the power to make informed decisions that impact workplace safety.

Let KPA show you how to take a data-driven approach to safety.